Engineering firm Siemens Gamesa is based in Spain. It offers onshore and offshore wind services, but also it manufactures wind turbines. In fact, it is the world’s second-largest wind turbine producer. In the field of wind energy, Siemens Gamesa is a technological innovator on a global scale.

No one can deny the fact Gamesa is also a global leader in the development, building, and sale of wind farms. The fact is the company has approximately 6,400 MW built and a portfolio of 24,000 MW in Europe, America, and Asia. Gamesa has facilities in China, India, Brazil, the US, and Europe. The company has operations in the Americas, Europe, Asia, Africa, and Oceania through its subsidiaries.

In short, Siemens Gamesa’s activity encompasses the design, production, installation, and maintenance of wind turbines.

Siemens Gamesa Renewable Energy SA – the facts

A Spain-based company Siemens Gamesa Renewable Energy SA is choice No1 if you want to spread your business in the wind renewable industry. Development and construction of wind farms is its working field.

Two business segments make up the Company’s operations: wind turbines and operation and maintenance.

The production of wind turbine generators as well as the planning, creation, and marketing of wind farms are included in the wind turbines industry (onshore and offshore).

The operation and maintenance industry is focused on providing operation and maintenance services using cutting-edge technologies in the renewable energy industry.

Pioneering technology of RecyclableBlade

With the RecyclableBlade, the first device to provide a comprehensive recyclable solution that is prepared for commercial usage both offshore and onshore, Siemens Gamesa is paving the way for a sustainable future.

The wind industry is still in its development, and Siemens Gamesa as one of its leaders is aware of its responsibilities to come up with sustainable solutions. There are two important things in industry sustainability. The first one is finding a way for disposing of wind turbine parts at the end of their service life. The other is to make more wind components recyclable. Siemens Gamesa’s goal is to produce 100% recyclable wind turbines by 2040.

Let’s make turbines recyclable

The need for wind circularity is growing, and some nations intend to impose tight regulations for wind turbine recycling as the number of installations and turbine sizes keep rising.

Several turbine parts, such as the tower and nacelle, have well-established recycling procedures. The composite materials utilized in rotor blades, however, have proven to be more difficult to recycle. That’s why Siemens Gamesa teams makes research together with reliable scientists. The company in June 2019 has opened its Sheffield Siemens Gamesa Renewable Energy Research Centre.

What’s the difference with recyclable turbines Siemens Gamesa produces

In the past, when wind turbines life span was over the industry couldn’t recycle the blades. The result, as usual, the blades ended up in landfills. What Siemens Gamesa did to change this?

The materials from their RecyclableBlade can now be recycled and used in other industries. That is a huge benefit for future generations. That’s why Siemens Gamesa’s ground-breaking RecyclableBlade technology is important. This is a game-changing move in the direction of the wind industry’s waste-free future. So, now, we have two benefits in one product – renewable energy and no waste.

Siemens Gamesa’s engineers used cutting-edge technology to create RecyclableBlade. They say it is a straightforward, reliable solution that is ready to be applied on offshore and onshore commercial wind farms. The engineers explain their new resin is the only modification to the blade manufacture process.

This indicates that expanding production and launching this recyclable good is not only feasible but has actually happened. The initial blades were created in 2021 and put into use in 2022.

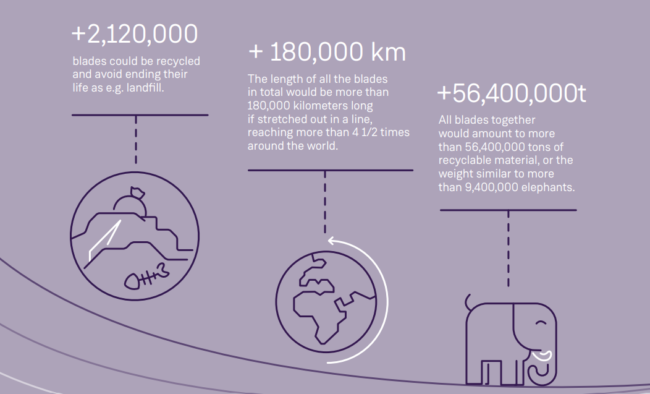

The RecyclableBlade is a crucial step in the effort to address the climate problems holistically. The RecyclableBlade would produce more than 10,000,000 tons of recyclable material. But only if applied to all offshore projects throughout the world. According to the schedule, it begins before 2050.

It’s not just easy like breeze – it’s more like a windstorm

In the midst of a contentious takeover attempt by its largest shareholder, wind turbine manufacturer Siemens Gamesa named Siemens Energy Chief Executive Christian Bruch as its new chairman last month.

The prospective merger and integration inside Siemens Energy, which unions reject owing to anticipated job cuts, according to Siemens Gamesa, was the natural next step, for the company said.

The hiring comes a week after the business failed its core profit margin target for the entire year as revenue fell. That happened primarily as a result of project delays and supply chain issues that halted the construction of wind turbine generators.

Despite strong demand from governments looking to wind energy to wean themselves off fossil fuels, manufacturing wind turbine components has become difficult in recent years. Difficulties come due to supply chain issues related to the COVID-19 pandemic, competition, and skyrocketing steel and aluminum prices – made worse by the war in Ukraine.

It will be better if the wind changes its direction

Following a 2.5% fall in 2021–2022, Siemens Energy anticipates its net loss to reduce significantly and sales to increase by 3%–7% in 2022–2033. Siemens Energy anticipates turning a profit in 2024, with Siemens Gamesa following a year later.

In order to better integrate the division and address quality issues at a next-generation turbine model, Siemens Energy is relying on its 4.05 billion euro bid for the final third of Siemens Gamesa that it does not already own.

Science makes the wind of change

The Sheffield-Siemens Wind Power Research Centre (S2WP), which was created to study wind power generation, was unveiled by Siemens Energy on December 14 at the University of Sheffield. Siemens Energy now owns 35% of Siemens Gamesa company and tends to raise its share.

Aiming to develop the most dependable, innovative, and efficient wind turbine generators that will be at the forefront of future onshore and offshore wind power systems, the cutting-edge Sheffield-Siemens Wind Power Research Centre (S2WP), located at the Kroto Innovation Centre, Broad Lane, Sheffield, employs about 20 people.

Siemens’ long-standing collaboration with the University’s Department of Electronic and Electrical Engineering led to the selection of the University of Sheffield. This Department houses the Electrical Machines and Drives Group. The group, led by Professor Qiang Zhu, conducts cutting-edge research on technologies that will be crucial to advancements in electrical power engineering in the future.

Access to the group’s 70 academic and research staff members as well as the University’s cutting-edge facilities are a key component of the relationship.

For the global market, the Siemens Research Center focuses on providing the overall technology, architecture, and design of onshore and offshore wind turbine generators, and machines that produce electricity from wind power.

The Siemens Wind Power project team has the immediate responsibility of growing its core group of generator specialists and working closely with the University of Sheffield to create in-house skills in generator design that maximizes power conversion.

Siemens already has key competency centers for the research and development of wind turbines at Keele, United Kingdom; Copenhagen, Denmark; Aachen, Germany; Delft, Netherlands; and most recently, Boulder, Colorado (USA).